Machines

POWER 5.0 PHASE 1 to control the various mechanical functions of industrial equipment or machinery.

₱18,125.00

ESV-Series (60 Hz) Applications Automatically boost water pressure to the house, apartment, villa, school, restaurant, school, etc. Automatically boost water pressure to garden sprinkler, heater, toilet, washing machine, sanitary equipment, etc. Features All-in-one booster pump unit, The ESV pump is mainly consisted of pump, motor, flow sensor, pressure tank and CPU Board. Auto run and boost water pressure while water is consumed. Auto stop running while no water is consumed. Dry running Shutdown protection to avoid motor burnout, ESV pump will shutdown within 1 minute when dry running occurs. Built-in thermal protector can prevent pipeline burst due to abnormal frequent on/off. Low Noise operation; Compact design for space saving. Always keep stable water pressure while using (hot) shower. Model Power Activation PressurEPrice ESV400 1/2 HP 1.8 bar 12,000.00 ESV800 1 HP 2.2 bar 20,800.00 Motor Specifications Voltage: 220V/60 Hz Enclosed class: IP54 Insulation: B Class Enclosed Fan cooled, 2P Motor Built in overload motor protector Operating Conditions Ambient Temp: Max 40 Celsius Liquid Temp: 0~40 Celsius Relative Humidity: Max 85% RH Working pressure: Max 5 bar Before starting the pump, make sure inlet pressure is lower than factory pre-set activation pressure.

₱26,000.00 ₱20,800.00

CREVICE NOZZLE D36X200 FOR BUDDY II AND MULTI II VACUUM CLEANER AND AERO21-01 W/D VACUUM CLEANER

₱140.00

WILO DEEP WELL JET PUMP-1STG(NO ADAPTER) - DWP 1.0 MATERIAL : CAST IRON HP 1.0 VOLTAGE 220 V - 60HZ RPM 3450

₱14,375.00

DEEP WELL JET PUMP-2STG(NO ADAPTER) - DWP 1.5 MATERIAL : CAST IRON HP 1.5 VOLTAGE 220V - 60HZ RPM 3450

₱2,400.00 ₱30,000.00

WILO DEEP WELL JET PUMP-2STG(NO ADAPTER) - DWP 2.0 CAST IRON HP 2.0 VOLTAGE : 220 V - 60HZ RPM 3450

₱25,500.00 ₱31,875.00

Densin C250E Electric Powered Heavy Duty Cold Water High - Pressure Cleaner | Model : C250E

₱275,000.00

Disposable Filter Bag 3 PCS/ Pack Fit To SL19130P

₱650.00

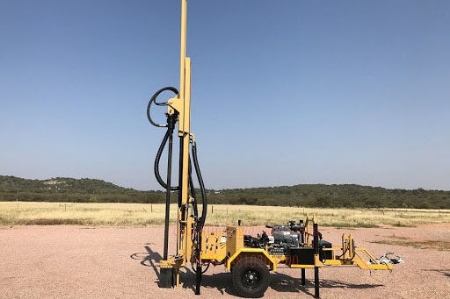

Dry use core drills are primarily designed for drilling into general house building materials such as soft facing stone, sandstone, brick and block. Dry core drills are designed to be used with hammer or percussion actions turned off and only rotary action applied. Gilson's coring equipment can be used to perform in a wide range of drilling applications. Applications include sampling concrete pavements, slabs, structures, cutting, and trimming of concrete specimens in sample preparation for testing. The equipment can also be used for sampling asphalt. You can use dry core bits without water to drill through brick and concrete blocks. On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. You can use dry core bits without water to drill through brick and concrete blocks . On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. Core drilling refers to the process of using a hollow drill to bore holes through certain surfaces. Through core drilling, teams can learn the density, chemical composition, strength, and other properties of specific materials. Three coring methods are practiced: conventional , wireline, and sidewall. Conventional coring, which refers to core taken without regard to precise orientation, encompasses arrange of coring devices and core barrels. As the name implies , this involves the cutting of a core at the bottom of the hole. In most cases it involves the drilling of hole with a hollow bit , allowing a solid cylinde r of uncut formation to enter an inner retainer or core barrel which may later be retrieved to surfACE

₱34,375.00 ₱27,500.00

Dry use core drills are primarily designed for drilling into general house building materials such as soft facing stone, sandstone, brick and block. Dry core drills are designed to be used with hammer or percussion actions turned off and only rotary action applied. Gilson's coring equipment can be used to perform in a wide range of drilling applications. Applications include sampling concrete pavements, slabs, structures, cutting, and trimming of concrete specimens in sample preparation for testing. The equipment can also be used for sampling asphalt. You can use dry core bits without water to drill through brick and concrete blocks. On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. You can use dry core bits without water to drill through brick and concrete blocks . On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. Core drilling refers to the process of using a hollow drill to bore holes through certain surfaces. Through core drilling, teams can learn the density, chemical composition, strength, and other properties of specific materials. Three coring methods are practiced: conventional , wireline, and sidewall. Conventional coring, which refers to core taken without regard to precise orientation, encompasses arrange of coring devices and core barrels. As the name implies , this involves the cutting of a core at the bottom of the hole. In most cases it involves the drilling of hole with a hollow bit , allowing a solid cylinde r of uncut formation to enter an inner retainer or core barrel which may later be retrieved to surfACE

₱41,250.00 ₱33,000.00

Dry use core drills are primarily designed for drilling into general house building materials such as soft facing stone, sandstone, brick and block. Dry core drills are designed to be used with hammer or percussion actions turned off and only rotary action applied. Gilson's coring equipment can be used to perform in a wide range of drilling applications. Applications include sampling concrete pavements, slabs, structures, cutting, and trimming of concrete specimens in sample preparation for testing. The equipment can also be used for sampling asphalt. You can use dry core bits without water to drill through brick and concrete blocks. On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. You can use dry core bits without water to drill through brick and concrete blocks . On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. Core drilling refers to the process of using a hollow drill to bore holes through certain surfaces. Through core drilling, teams can learn the density, chemical composition, strength, and other properties of specific materials. Three coring methods are practiced: conventional , wireline, and sidewall. Conventional coring, which refers to core taken without regard to precise orientation, encompasses arrange of coring devices and core barrels. As the name implies , this involves the cutting of a core at the bottom of the hole. In most cases it involves the drilling of hole with a hollow bit , allowing a solid cylinde r of uncut formation to enter an inner retainer or core barrel which may later be retrieved to surfACE

₱51,250.00 ₱41,000.00

Dry use core drills are primarily designed for drilling into general house building materials such as soft facing stone, sandstone, brick and block. Dry core drills are designed to be used with hammer or percussion actions turned off and only rotary action applied. Gilson's coring equipment can be used to perform in a wide range of drilling applications. Applications include sampling concrete pavements, slabs, structures, cutting, and trimming of concrete specimens in sample preparation for testing. The equipment can also be used for sampling asphalt. You can use dry core bits without water to drill through brick and concrete blocks. On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. You can use dry core bits without water to drill through brick and concrete blocks . On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. Core drilling refers to the process of using a hollow drill to bore holes through certain surfaces. Through core drilling, teams can learn the density, chemical composition, strength, and other properties of specific materials. Three coring methods are practiced: conventional , wireline, and sidewall. Conventional coring, which refers to core taken without regard to precise orientation, encompasses arrange of coring devices and core barrels. As the name implies , this involves the cutting of a core at the bottom of the hole. In most cases it involves the drilling of hole with a hollow bit , allowing a solid cylinde r of uncut formation to enter an inner retainer or core barrel which may later be retrieved to surfACE

₱67,500.00 ₱54,000.00

Dry use core drills are primarily designed for drilling into general house building materials such as soft facing stone, sandstone, brick and block. Dry core drills are designed to be used with hammer or percussion actions turned off and only rotary action applied. Gilson's coring equipment can be used to perform in a wide range of drilling applications. Applications include sampling concrete pavements, slabs, structures, cutting, and trimming of concrete specimens in sample preparation for testing. The equipment can also be used for sampling asphalt. You can use dry core bits without water to drill through brick and concrete blocks. On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. You can use dry core bits without water to drill through brick and concrete blocks . On the other hand, wet core bits require water cooling for safe operation. People doing DIY projects often find dry core bits to be more convenient and easier to work with. However, wet core bits are typically more powerful. Core drilling refers to the process of using a hollow drill to bore holes through certain surfaces. Through core drilling, teams can learn the density, chemical composition, strength, and other properties of specific materials. Three coring methods are practiced: conventional , wireline, and sidewall. Conventional coring, which refers to core taken without regard to precise orientation, encompasses arrange of coring devices and core barrels. As the name implies , this involves the cutting of a core at the bottom of the hole. In most cases it involves the drilling of hole with a hollow bit , allowing a solid cylinde r of uncut formation to enter an inner retainer or core barrel which may later be retrieved to surfACE

₱81,250.00 ₱65,000.00

Duplex booster pump systems are designed to lead, lag, and alternate every 24 hours of run time. This ensures even wear between each pump. In the event one pump cannot maintain the pressure, the second pump will turn on to assist. Operational risks in a pressure boosting system. Poor control of the boosting operation can damage pumps and cause pipes to leak. Over time, this can result in excessive water consumption , spiralling costs, and even indoor flooding. A booster pump is a device that increases low water pressure and flow. It provides the extra boost needed to bring your water pressure to the desired level. A water booster pump provides pressure to move water from a storage tank or throughout a whole house or commercial facility. A booster system should not run continuously, particularly if there is no demand for water. Once the pump has satisfied the system pressure, a minimum run timer is actuated, and the pump will run for a preset time. The run cycle is usually five to seven minutes. Without elaborating on specific applications: A 'pressure' pump generally operates with the inlet under 'neutral' or negative pressure, while a 'booster' pump, typically, operates with 'supercharged' inlet. That is to say, it increases positive pressure provided by another pump or by gravity. If you think your booster pump switches off too quickly, it means that the switch- off pressure has been set too low. The problem can be solved by increasing the pressure. If you think your booster pump switches on too quickly, it means that the switch -on pressure has been set too high.

₱272,500.00 ₱218,000.00

Min: ₱0.00 Max: ₱1,162,500.00

₱0 ₱1162500

Recently viewed products