Products tagged with 'stainless steel'

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-10-1-1-T

MS4-10-1-1-T

Stainless Steel Submersible Borehole Motor For 4" & 6" Well Casing Diameter

₱175,000.00 ₱21,875.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-15-1-1-T

MS4-15-1-1-T

Stainless Steel Submersible Borehole Motor For 4" & 6" Well Casing Diameter High Quality Thrust Bearings The trust bearing is of the kingsburrY type lubricated by the internal fluid. During operation a wedge of water is drawn between the stainless steel pivot shoes and carbon disc to carry the thrust load generated by the pump. Located inside and at the bottom of the motor, the bearing is sealed away from sand and other contaminants. Sand Resistant Slinger and Lip Seals A stainless steel slinger and slinger guide are also closely fit to help prevent sand entry. Double rubber seals are installed to prevent well water and contaminants from entering the motor. High Reliable Carbon Bearing Two water lubricated carbon bearings are used as guide bearings. These have extremely large surface area and result in extra alignment support-less whipping and acts as a steady bushing. Water-Filled Design The motor lubrication is provided by the internal cooling water consistings of a water, anti-freeze and anti-rust mixture good to 30°C (-22°F). This mixture is installed at the factory. Two water plugs are located near of the top of the motor and are used by the installer to check the water level or to the top off needed before installation. Complete Corrosion and Water-Tight Protection All main motor components are made of stainless steel: including the can housing (water tight type motors have baked epoxy coated steel housing), Shaft and bolts. All other motor parts are coated with the baked epoxy coating.

₱22,500.00 ₱28,125.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-20-1-1-T

MS4-20-1-1T

This depends upon the depth of the borehole to ground level and then the distance from the ground level to the final end point e.g. where the water tank is sited. The further the distance, the higher the pressure requirements of the borehole pump to prevent the water from trickling out. Submersible borehole pumps are a type of submersible pump. They are centrifugal pumps driven by a submersible motor. As they usually draw in the fluid directly without a suction line, they must constantly be submerged in the fluid handled. Starter borehole pumps can run for up to 24 hours. However, your everyday borehole pump will run between 6 & 8 hours. It is not good for your borehole pump to run continuously. If you run electrical pumps continuously, your utility bill will skyrocket.

₱22,500.00 ₱30,625.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-30-1-1-T

MS4-30-1-1-T

The diameter of the borehole is usually around 120 to 160 mm, and its depth can reach up to 300 meters, although depth of about 40 meters is more common. Your pump and its control system must also meet the specific conditions as well as the high demands on reliability. This depends upon the depth of the borehole to ground level and then the distance from the ground level to the final end point e.g. where the water tank is sited. The further the distance, the higher the pressure requirements of the borehole pump to prevent the water from trickling out. Submersible borehole pumps are a type of submersible pump . They are centrifugal pumps driven by a submersible motor. As they usually draw in the fluid directly without a suction line, they must constantly be submerged in the fluid handled.

₱34,500.00 ₱43,125.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-30-3-2-T

MS4-30-3-2-T

The diameter of the borehole is usually around 120 to 160 mm, and its depth can reach up to 300 meters, although depth of about 40 meters is more common. Your pump and its control system must also meet the specific conditions as well as the high demands on reliability. This depends upon the depth of the borehole to ground level and then the distance from the ground level to the final end point e.g. where the water tank is sited. The further the distance, the higher the pressure requirements of the borehole pump to prevent the water from trickling out. Submersible borehole pumps are a type of submersible pump. They are centrifugal pumps driven by a submersible motor. As they usually draw in the fluid directly without a suction line, they must constantly be submerged in the fluid handled.

₱29,000.00 ₱36,250.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-50-1-1-T

MS4-50-1-1-T

Stainless Steel Submersible Borehole Motor For 4" & 6" Well Casing Diameter High Quality Thrust Bearings The trust bearing is of the kingsburry type lubricated by the internal fluid. During operation a wedge of water is drawn between the stainless steel pivot shoes and carbon disc to carry the thrust load generated by the pump. Located inside and at the bottom of the motor, the bearing is sealed away from sand and other contaminants. Sand Resistant Slinger and Lip Seals A stainless steel slinger and slinger guide are also closely fit to help prevent sand entry. Double rubber seals are installed to prevent well water and contaminants from entering the motor. High Reliable Carbon Bearing Two water lubricated carbon bearings are used as guide bearings. These have extremely large surface area and result in extra alignment support-less whipping and acts as a steady bushing. Water-Filled Design The motor lubrication is provided by t he internal cooling water consistings of a water, anti-freeze and anti-rust mixture good to 30 °C (-22°F). This mixture is installed at the factory. Two water plugs are located near of the top of the motor and are used by the installer to check the water level or to the top off needed before installation. Complete Corrosion and Water-Tight Protection All main motor components are made of stainless steel: including the can housing (water tight type motors have baked epoxy coated steel housing), Shaft and bolts. All other motor parts are coated with the baked epoxy coating.

₱53,200.00 ₱66,500.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-50-3-2-T

MS4-50-3-2-T

Stainless Steel Submersible Borehole Motor For 4" & 6" Well Casing Diameter High Quality Thrust Bearings The trust bearing is of the kingsburry type lubricated by the internal fluid. During operation a wedge of water is drawn between the stainless steel pivot shoes and carbon disc to carry the thrust load generated by the pump. Located inside and at the bottom of the motor, the bearing is sealed away from sand and other contaminants. Sand Resistant Slinger and Lip Seals A stainless steel slinger and slinger guide are also closely fit to help prevent sand entry. Double rubber seals are installed to prevent wel l water and contaminants from entering the motor. High Reliable Carbon Bearing Two water lubricated carbon bearings are used as guide bearings. These have extremely large surface area and result in extra alignment support-less whipping and acts as a steady bushing. Water-Filled Design The motor lubrication is provided by the internal cooling water consistings of a water, anti-freeze and anti-rust mixture good to 30°C (-22°F). This mixture is installed at the factory. Two water plugs are located near of the of the motor and are used by the installer to check the water level or to the top off needed before installation. Complete Corrosion and Water-Tight Protection All main motor components are made of stainless steel : including the can housing (water tight type motors have baked epoxy coated steel housing), Shaft and bolts. All other motor parts are coated with the baked epoxy coating.

₱50,000.00 ₱62,500.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS4-75-3-1-T

MS4-75-3-1-T

Stainless Steel Submersible Borehole Motor For 4" & 6" Well Casing Diameter High Quality Thrust Bearings The trust bearing is of the kingsburry type lubricated by the internal fluid. During operation a wedge of water is drawn between the stainless steel pivot shoes and carbon disc to carry the thrust load generated by the pump. Located inside and at the bottom of the motor, the bearing is sealed away from sand and other contaminants. Sand Resistant Slinger and Lip Seals A stainless steel slinger and slinger guide are also closely fit to help prevent sand entry. Double rubber seals are installed to prevent well water and contaminants from entering the motor. High Reliable Carbon Bearing Two water lubricated carbon bearings are used as guide bearings. These have extremely large surface area and result in extra alignment support- less whipping and acts as a steady bushing. Water-Filled Design The motor lubrication is provided by the internal cooling water consistings of a water, anti-freeze and anti-rust mixture good to 30°C (-22°F). This mixture is installed at the factory. Two water plugs are located near of the top of the motor and are used by the installer to check the water level or to the top off needed before installation. Complete Corrosion and Water-Tight Protection All main motor components are made of stainless steel: including the can housing (water tight type motors have baked epoxy coated steel housing), Shaft and bolts. All other motor parts are coated with the baked epoxy coating.

₱75,000.00 ₱93,750.00

STAINLESS STEEL SUBMERSIBLE BOREHOLE MOTOR FOR 4" & 6" WELL CASING DIAMETER - MS6-100-3-2-T

MS6-100-3-2-T

Stainless Steel Submersible Borehole Motor For 4" & 6" Well Casing Diameter High Quality Thrust Bearings The trust bearing is of the kingsburry type lubricated by the internal fluid. During operation a wedge of water is drawn between the stainless steel pivot shoes and carbon disc to carry the thrust load generated by the pump. Located inside and at the bottom of the motor, the bearing is sealed away from sand and other contaminants. Sand Resistant Slinger and Lip Seals A stainless steel slinger and slinger guide are also closely fit to help prevent sand entry. Double rubber seals are installed to prevent well water and contaminants from entering the motor. High Reliable Carbon Bearing Two water lubricated carbon bearings are used as guide bearings. These have extremely large surface area and result in extra alignment support-less whipping and acts as a steady bushing. Water-Filled Design The motor lubrication is provided by the internal cooling water consistings of a water, anti-freeze and anti-rust mixture good to 30°C (-22°F). This mixture is installed at the factory. Two water plugs are located near of the top of the motor and are used by the installer to check the water level or to the top off needed before installation. Complete Corrosion and Water-Tight Protection All main motor components are made of stainless steel: including the can housing (water tight type motors have baked epoxy coated steel housing), Shaft and bolts. All other motor parts are coated with the baked epoxy coating.

₱81,500.00 ₱101,875.00

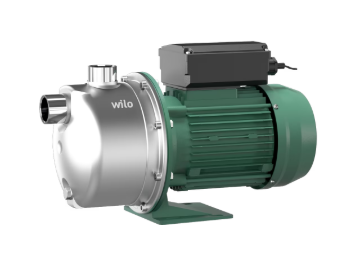

JET WJ SERIES - WJ-201-X-EM/6

WJ-201-X-EM/6

WILO JET WJ SERIES - WJ-201-X-EM/6 MATERIAL STAINLESS STEEL HP 0.50 VOLTAGE 220 V - 60HZ RPM 3450

₱17,500.00 ₱10,875.00

JET WJ SERIES - WJ-202-X-EM/6/B

WJ-202-X-EM/6/B

WILO PUMP WJ-202-X-EM 6/B SELF PRIMING PUMP STAINLESS STEEL 0.75 HP VOLTAGE 220 V - 60 HZ RPM 3450

₱11,500.00

JET WJ SERIES - WJ-203-X-EM/6/B

WJ-203-X-EM/6/B

WILO JET WJ SERIES - WJ-203-X-EM/6/B STAINLESS STEEL 1.0 HP VOLATGE 220 V - 60HZ RPM 3450

₱12,000.00