Drilling or Fastening

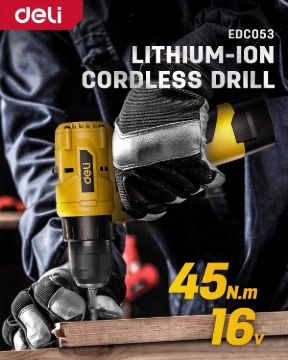

Deli Lithium-Ion Cordless Drill EDC053

EDC053

EDC053 Deli Lithium-Ion Cordless Drill 16V 45NM 2.0Ah*2

₱7,218.00

Deli Lithium-Ion Cordless Drill EDC120

EDC120

EDC120 Lithium-Ion Cordless Drill 20V 45Nm 2.0Ah*2

₱9,988.00

Deli Lithium-Ion Cordless Drill EDE-DZ16-1D2

EDE-DZ16-1D2

EDE-DZ16-1D2 Lithium-Ion Cordless Drill 16V 45Nm 2.0ah*2

₱8,468.00

Deli Lithium-Ion Cordless Drill EDE-DZ20-2

EDE-DZ20-2

EDE-DZ20-2 Lithium-Ion Cordless Drill 20v 13mm

₱10,328.00

Deli Lithium-Ion Cordless Drill EDE-DZ20-2D2

EDE-DZ20-2D2

EDE-DZ20-2D2 Lithium-Ion Cordless Drill 20v 13mm 2.0ah*2

₱15,238.00

Deli Lithium-Ion Cordless Drill EDL-DZ12-4A2

EDL-DZ12-4A2

EDL-DZ12-4A2 Lithium-Ion Cordless Drill 12V 30NM 2.0Ah*1

₱2,498.00

Deli Lithium-Ion Cordless Drill EDL-DZ12-5A2

EDL-DZ12-5A2

EDL-DZ12-5A2 Lithium-Ion Cordless Drill 12V 30NM 2.0Ah*1

₱2,748.00

Deli Lithium-Ion Cordless Drill Set EDL-DZ12-6A2

EDL-DZ12-6A2

EDL-DZ12-6A2 Lithium-Ion Cordless Drill Set 12V 30NM 2.0Ah*1

₱3,698.00

Deli Lithium-Ion Impact Drill EDC054

EDC054

EDC054 Deli Lithium-Ion Impact Drill 16V 45NM 2.0Ah*2

₱7,718.00

Deli Lithium-Ion Impact Drill EDC150-2

EDC150-2

EDC150-2 Lithium-Ion Impact Drill 20V 45N.m Brushless

₱10,488.00

Deli Lithium-Ion Impact Drill EDE-CZ16-1A2

EDE-CZ16-1A2

EDE-CZ16-1A2 Lithium-Ion Impact Drill 16V 45Nm 2.0ah*1

₱7,728.00

Min: ₱0.00 Max: ₱625,000.00

₱0 ₱625000